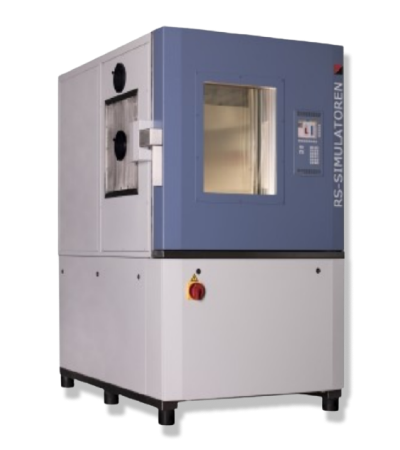

Temperature & Climatic Test Chambers

The Temperature and Climatic Test Chamber is a compact test system with a high level of performance. It is use to create specific and highly controlled temperature and humidity conditions to simulate a real environmental conditions. The continues development of the modular system protects your investment for the future. Area of applications are in quality assurance, research and development of components and products a such as electronics, energy storage, material processing and so on.

| Standard Technical Data |

|

|---|---|

| Size |

|

| Design |

|

| Optional |

|

Temperature & Climatic Walk-In Test Chambers

Temperature and Climatic Walk-In Test Chamber is used to simulate specific climate and temperature environments required for stability testing, accelerated stress testing and conditioning of in-organic materials, biomass, pharmaceuticals and food. They excel in laboratory use with their fast heating and cooling rates as well as excellent distribution, high stability and uniformity of temperature and relative humidity.

| Standard Technical Data |

|

|---|---|

| Design | Individual chambers modules, fully assembled in our production are screwed at the site and put into operation. A preliminary examination if the whole chamber and all performance data is already done in our test. Difficult structure of local situations is avoided. The depth of a chamber can increased by an additional element itself at a later time. |

| Options |

|

| Applications |

|

Thermal Shock Tester

The testing chamber type ST2K is the new generation compact testing facility. The feature innovative technology, great flexibility and board area of applications. With these system, it will make solid investment into the future of inspection and measuring technology. The type ST2K features system integration capabilities , enabling continuous extendibility of inspection facility.

| Standard Technical Data |

|

|---|---|

| Size |

|

| Design |

|

| Optional |

|

Chamber With External Air Conditioning Frame -ETA

Control units are suitable for external supply unit testing space. In the ETA type, the temperature or required air is generated and transported either through a large rectangle through or with insulated hoses into the external test space. The temperature control is carried out in a convection process. With both types of coupling to an external test space vibration transmission is greatly reduced. The master and slave function allows multiple ETA connect to a test space.

| Standard Technical Data |

|

|---|---|

| Size |

|

| Options |

|

| Applications |

|

Battery Test System

Lithium-Ion batteries and cells are already used in many areas of daily life. As self-evident as the use of cell phones and notebooks, the more effort has to be expended on testing technology that is as safe as possible. The high energy density on the onehanded harbors the dangers on the other. Kindly contact us for more explanation about this battery test system.

| Standard Technical Data |

|

|---|---|

| Size |

|

| Options |

|